The gearbox assembly line is a key facility for the production of core automotive components. By integrating automated/semi-automated systems in multiple links such as processing, assembly, and testing, efficient, standardized and large-scale production of gearboxes is achieved.

I. Overall layout of gearbox production line

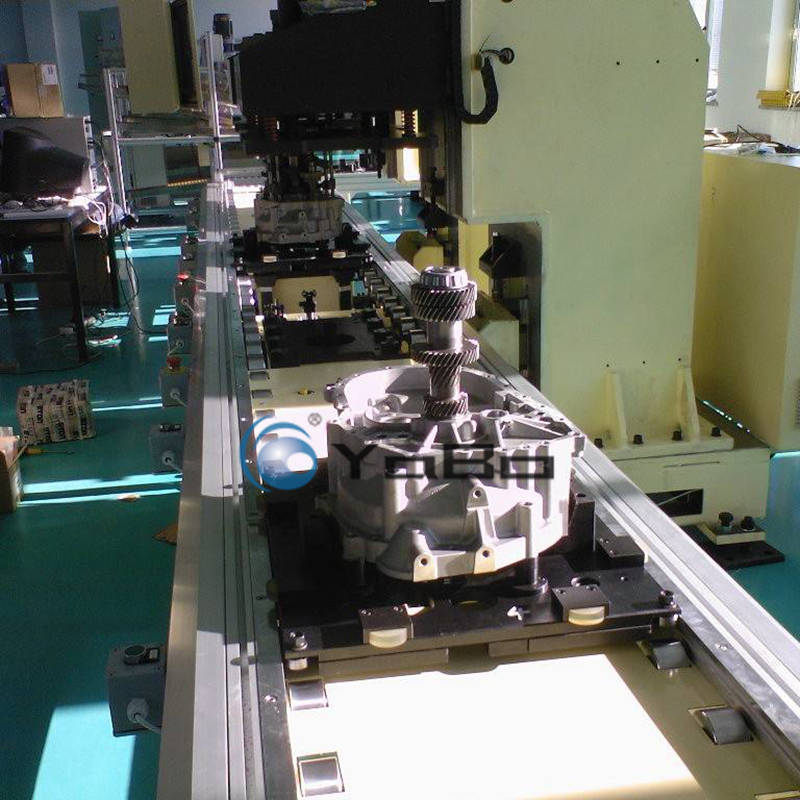

1. The chain/roller conveyor line is used as the main line, the shell is fixed on the pallet through tooling fixtures, and flows along the main line in single direction 2, realizing automatic transmission between each process.

Equipped with a robot/robotic arm to assist in loading and unloading (the manual console works in conjunction with the robot) to reduce manual intervention and improve work efficiency.

3. Vision inspection system: Identify part defects and assembly deviations through industrial cameras (such as damaged gear chamfers, shell scratches).

II. The gearbox (manual MT, automatic AT, dual clutch DCT, stepless CVT, etc.) has a precise structure (including hundreds of parts such as gears, shafts, shells, and hydraulic valves). The core functions of its assembly line are:

1. Complete precise assembly and functional integration of parts;

2. Ensure product consistency through full-process quality monitoring;

3. Meet the flexible production needs of gearboxes of different models and specifications.

This gearbox production line focuses on "high-precision assembly + full-process inspection", reduces manual intervention through automated equipment, and combines error prevention and traceability technologies to ensure product quality. It is suitable for small and medium-sized batch or large-scale mass production scenarios. Specific process details may be slightly adjusted due to differences in gearbox type (manual/automatic/DCT/AT), displacement, and structure.